Effect of Microwave Hot Air Combined Drying Technology on the Quality of Gongfu Black Tea

The current production technology of Gongfu black tea is as follows: fresh leaves 1 rhombus withering kneading fermentation microwave drying equipment, in which drying is the process of losing most of the moisture in the initial processing of black tea. Through this process, the aroma of tea can be further developed, and the purpose of storage and transportation can be achieved.

Most of the current black tea in China is dried by hot air, which has the advantages of less investment, low energy consumption and higher aroma of tea. The disadvantage is that in the process of hot air drying, the tea temperature rises for a long time, which causes the inactivation of enzymes in time and then affects the taste of tea. At present, the microwave drying of black tea plays an increasingly important role in the processing of agricultural products.

It has fast drying speed and short drying time. Its drying time is 10-100 of the general method. It is beneficial to maintain the color, fragrance and taste of the product, and has less loss of nutrients. At the same time, microwave drying can also form good rehydration performance. However, after a lot of experiments, the author found that the microwave drying process, in addition to fast drying speed and strong taste, has a loose appearance, aroma, soup color and other major factors are not as good as the traditional hot air drying tea.

Therefore, on the basis of the existing drying process, it is of great practical significance for the development of enterprises and the progress of the whole industry to innovate boldly, produce excellent black tea products with good aroma and taste, and enhance the competitiveness of products in the market.

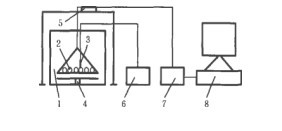

In the drying process of black tea, the method of combined drying by microwave and hot air (hereinafter referred to as combined drying) was innovated in this study. The dried tea was directly laid on the conveyor belt of the microwave dryer, dried by two groups of microwave power at 15 revolutions, and then dried by the aroma extractor at 110 C until the moisture content was below 7%. The best quality was obtained.

The experimental results showed that the best technological parameters for drying Gongfu Black Tea by Microwave-hot air combined drying were as follows: the appropriate fermented Gongfu Black Tea was quickly deactivated by microwave (two groups of 15 rotations), the fermentation was terminated in time, and then dried fully by hot air (110 C) to improve the aroma of tea.

Black tea produced by Microwave-hot air combined drying process has sweet aroma, mellow taste, bright red soup color and good quality, which is superior to traditional hot air drying and microwave drying products. Because of the influence of raw materials, the energy consumption of Microwave-hot air combined drying and hot air drying has not been evaluated and compared. Therefore, this paper only discussed the influence of the quality of dried black tea. Before its application, it is necessary to evaluate and calculate the energy consumption.