Development of microwave drying

With clean electricity as energy source, China has stepped into the world's largest power country because of its increasingly abundant electricity. The ratio of electricity price to coal price is gradually decreasing. Therefore, microwave drying and other energy-based drying methods are expected in the 21st century.

There will be a marked growth trend.

Microwave drying equipment will play an important role in solving heavy materials, precious materials and difficult to dry materials in the future. Of course, microwave drying can also be used for drying small diameter logs, veneers, veneers and crushed materials. In 1972, Mimi Yoshida et al. studied the microwave drying of veneer, using a small intermittent microwave drying device to dry Eucalyptus rotary veneer. The results showed that the drying speed increased with the increase of output power, especially under the fiber saturation point, the effect was greater. The drying defect is the occurrence of spot carbonization, which is related to the increase of the surface temperature of the veneer. Carbonization will occur when the surface temperature is above 150 C. Energy efficiency is related to microwave output power, final moisture content, veneer thickness, and the volume of veneer dried. From 1977 to 1978, Harbin No. 2 Transformer Plant, Harbin Wood-based Panel Plant and Forestry Engineering Department of Northeast Forestry College cooperated together. For the first time, microwave energy was used to dry particles, and some results were obtained. It was considered that microwave energy drying particles (fragments) was technically feasible. Zhu Zhengxian studied the microwave drying of Small-Diameter Birch logs in 1995. It was considered that microwave drying was technically feasible for Small-Diameter Birch logs. In 1998, Wang Liyu studied the microwave drying technology of small diameter round and oblique section of Robinia pseudoacacia. It was preliminarily suggested that it was feasible to use microwave drying technology for small diameter round and oblique section of Robinia pseudoacacia. The drying standard of oblique section should be softer than that of circular section.

There are two methods of microwave wood drying, that is, the rapid drying of wood by microwave and the balancing of moisture content by the dielectric properties of wood. In 1970 H. Resch et al. used microwave - hot air dryers to balance the moisture content of dried but still very wet coniferous veneers.

Drying is optional because wet regions absorb more microwave. The bonding force of microwave-dried veneer is equal to or better than that of the first drying or hot air-dried veneer, and the results of the seam test of microwave-dried veneer are not obviously lower than those of the other two drying methods. Microwave drying can prevent over-drying, and make veneer softer, after drying due to splitting or damage reduction, microwave drying veneer less than hot air drying veneer. Vasishth et al. studied the veneer microwave drying, the Citi Pine veneer samples were dried by microwave and conventional equipment, and the electron microscope observation and photography showed that the cell wall of the veneer dried by microwave was not damaged.

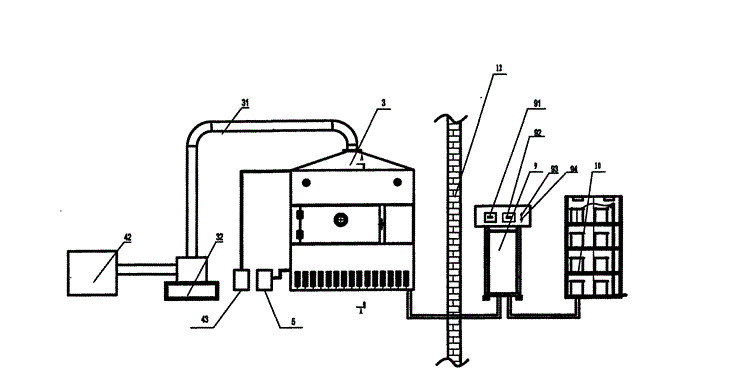

Microwave drying of wood may be used in the second stage of two-stage drying, that is, in the stage of low moisture content drying, which can give full play to its drying characteristics and reduce energy consumption appropriately. For example, dehumidification and microwave combined drying, air drying and microwave two-stage drying have the advantages of energy saving and rapid drying. The combined drying of these different methods is expected to have a better development prospects in the 21st century.

2 microwave moisture measurement

Microwave drying is usually done by microwave heating or dielectric constant measurement. The biggest advantage of microwave heating drying method is that it is fast and suitable for on-line determination, so it has important significance in water determination and on-line moisture measurement and control in production process. Another way to measure moisture by microwave technology is to measure the change of dielectric constant of material. In the microwave band, the dielectric constant of water is 50~81.

The dielectric constant of many other materials, such as plant fiber is 2.

4) much higher. So the dielectric constant of the material will have a great change if the moisture content changes slightly, so the moisture content of the material can be measured by measuring the dielectric constant change. Yin Xiaobing of Yunnan Academy of Forestry Sciences put forward the method of microwave oven-oven (WB-Oven) to measure the moisture content of Yunnan pine wood by microwave oven-oven method.

HX) method to improve the efficiency of determining wood moisture content. The method is divided into two steps to make the sample completely dry. The first step is to apply the principle of microwave drying to make the sample quickly dried in the microwave oven. The second step is to make the sample dried in the oven at constant temperature until it is completely dry. The total determination time of this method is 4-6 hours, which is 7 hours shorter than that of the conventional oven drying method, and the determination accuracy is in accordance with the national standard.

The method is the same and the operation is convenient.

3 Microwave Modified Wood

In recent years, there has been research on microwave modified wood in the world.

At the symposium entitled "The Future of Eucalyptus Products" sponsored by IFF in 200, Professors Vinden and Torgovnikov of the Forestry College of the University of Melbourne, Australia, introduced the microwave wood modification technology developed by them. They suggested that microwave could improve the axial and radial permeability of wood and consequently the preservation of refractory tree species. Processing properties, they also use microwave treatment to make a new type of wood products, this product can be made into a multi-layer diameter section of the gap, can also be microwave treatment and not microwave (or light microwave treatment) of the material layer together, can also use microwave irradiation of certain parts of the wood, forming different modified layer. The research on wood modified by microwave in our country is in the tentative stage. Wang Ximing and others have made microwave modified wood with poplar and Manchurian ash as test materials.

Preliminary research. The results showed that microwave treatment could improve some properties of wood, especially hardwood. The microwave treatment destroyed the weak links of the pore membrane on the cell wall of wood, precipitated or redistributed the extract of wood, and the density of wood.

The drying speed of wood is accelerated by decreasing the ratio of tangential to radial shrinkage and increasing the water absorption of wood.