Study on microwave drying process of thick wood

Abstract: through the contrast experiment of thick wood microwave drying, we explored the drying process. The field intensity distribution and heating efficiency in the two kinds of microwave chambers were measured and analyzed. The variation of temperature, drying rate and moisture content in the drying process of thick wood under the same frequency, different power and different intermittent time were studied. The formation of positive heat source and the determination of critical drying temperature were further discussed. The microwave drying equipment under temperature control not only avoids the phenomenon of temperature out of control, but also has higher drying efficiency.

Key words: microwave; critical temperature; positive heat source; wood

Microwave drying of wood is one of the most effective rapid drying methods. After more than 30 years of efforts, although great achievements have been made, the depth and breadth of research is still insufficient. If the drying process is not properly controlled, it is easy to occur "temperature out of control" phenomenon in practical application, and it is easy to burst and carbonize in the wood, mainly because the temperature distribution in the wood microwave drying process is not properly understood. There are two opinions on the temperature distribution in wood microwave drying process. One is "body heat source", that is, the temperature changes with thickness in the whole process of wood microwave drying.

The distribution of degree (radial) is uniform, and there is no temperature gradient; the other is "positive heat source". The temperature distribution of wood microwave drying process with thickness (radial) is not uniform, temperature distribution follows the gradient law of high inside and low outside. The relationship between temperature gradient and moisture content gradient in the whole process of microwave drying of thick wood was analyzed quantitatively. The critical drying process parameters of each stage were summarized. The internal temperature was controlled by limiting the surface temperature to prevent the occurrence of "temperature out of control". It is more economical and environmentally friendly to prevent wood from internal combustion by this physical method than by adding chemical flame retardants.

1 basic principles and characteristics of wood microwave drying

1.1 basic principles of wood microwave drying

Microwave is a kind of electromagnetic wave. The microwave (frequency: 2 450 MHz) used in this experiment is decimeter band, and the band code is LS. Electromagnetic waves have wave-particle duality. According to quantum theory, the energy of microwave radiation is discontinuous, consisting of one "energetic electron", each quantity.

The energy of the sub is E=hf, where h=6.626 * 10-34 J. S is the Planck constant and F is the frequency. This quantum effect should be taken into account when microwave drying.

Wood is a kind of biological material composed of macromolecule material and low molecular substance. Macromolecular materials consist of cellulose, hemicellulose and lignin, and low molecular substances consist of wood extracts (esters and glycerol, etc.) and ash powder. Usually wood contains a certain amount of moisture. Wood with a certain amount of moisture undergoes energy conversion under the action of microwave. Wood with high, low and water molecules absorb microwave energy while the temperature rises rapidly. Water molecules get rid of adsorption and bondage and gradually leave the wood. Wood is dried.

1.2 characteristics of wood microwave drying

Timeliness, integrity, selectivity and high efficiency of wood microwave heating have been recognized. Whether there is a "positive heat source" has not been decided, and the conditions for its formation and stability have not been studied in detail. The temperature gradient of wood microwave drying process from the center to the outside is proved to be objective by experiments. At the same time, due to the existence of "positive heat source", the phenomenon of "temperature runaway" occurs when the moisture content of wood is low at the end of drying. In this study, the temperature of the drying process is realized by determining the critical drying process parameters. Degree control.

2 materials and methods

2.1 experimental materials

The species are Cuninghamialanceolata and Pinusmasomiana. The test material should be taken from the same part of the same tree, no knots, no decay, no cracks and other defects, each plane is smooth and clean. The material and dimensions of the specimens are: (1) from 4 dimensions.

Wood blocks composed of equal pieces of wood: 190 mm x 50mm x 52 mm, 190 mm x 64mm x 52 mm, 300 mm x 64mm * 52 mm;

(2) 6 pieces of wood chips of equal size: 190 mm x 64 mm x 78mm, 190 mm x 50mm x 78mm, 300 mm

* 64 mm x 78mm, 300 mm x 50 mm * 78mm; (3) thick Chinese Fir with different sizes: 11 pieces 100 mm * 40 mm * 80mm.

2 blocks 200 mm x 40 mm * 80mm; pine pines of different sizes: 10 pieces 200 mm x 40 mm x 80mm, 2 200 mm *

80 mm x 80mm, 2 yuan 105 mm x 105 mm x 105mm; (4) 27 small beaker, 1 large beaker and 2 400 mm * 300 mm

Thin glass.

2.2 experimental equipment

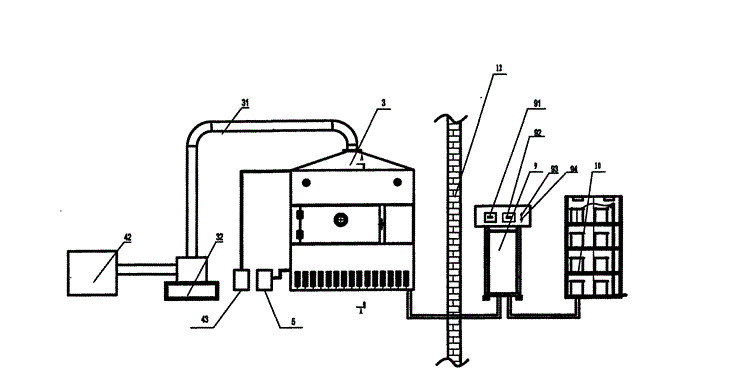

The heating equipment used is Sanle WXD4S-24 made in Nanjing and Haier MF-2480 EGS(N) microwave products made in Harbin, the microwave frequency is 2 450 MHz, the output power is 4 kW and 800 W respectively, the temperature testing equipment is infrared non-contact surface temperature measuring instrument, the temperature measuring range is (-18) -375, the quality testing equipment is FEJ-3000D Friedel electronic balance, accuracy is 1 g; DHG-9240A electrothermal constant temperature blast drying box and electronic stopwatch.

2.3 experimental method

27 small beakers containing 50 mL water were evenly divided into 3 layers and placed in the Sanle WXD4S-24 microwave oven. Each layer was 8 cm high, separated by thin glass. Each layer contained 9 cups of water, 3 rows and 3 rows. After opening the 4 kW microwave for 120 s, the water temperature was measured, and the average value was measured 3 times. A large beaker containing 1 000 mL water was placed in the MF-2 480 EGS (N) rotating wave microwave oven of Haier. After opening 800 W microwave for 1 minute, the water temperature was measured and the average value was obtained three times. The inhomogeneity of microwave field and heating efficiency in Sanle microwave oven and the heating efficiency of Haier microwave oven are calculated respectively.

The wet wood was soaked in water for different times at room temperature to give different moisture content.